Raise Efficiency: Necessary Tips for Maintaining Undercarriage Parts Performance

Raise Efficiency: Necessary Tips for Maintaining Undercarriage Parts Performance

Blog Article

Secret Elements: Undercarriage Parts for Heavy Machinery

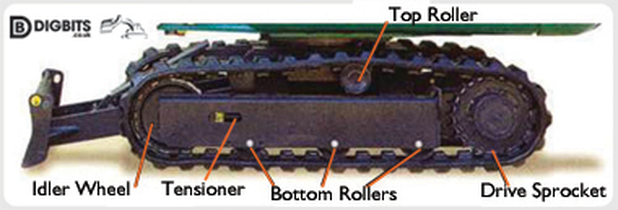

In the realm of hefty equipment, the undercarriage offers as a crucial foundation that makes sure the smooth procedure and longevity of the equipment. Key components such as track footwear, rollers, idlers, sprockets, and track chains play a crucial function in the capability and performance of these massive machines.

Track Footwear

Track footwear play an essential duty in the efficiency and sturdiness of heavy machinery's undercarriage system. Track shoes come in numerous styles and materials to match different operating conditions and surfaces.

The layout of track shoes is crafted to give optimum ground contact, minimizing slippage and enhancing the maker's capacity to browse tough surfaces. Appropriate maintenance and regular evaluation of track shoes are necessary to stop early wear and make certain the undercarriage system's long life. Any type of indicators of wear, such as uneven wear patterns or too much damages, must be addressed without delay to stay clear of costly repair services and downtime.

Rollers

Rollers are critical parts of the undercarriage system in hefty equipment, operating in conjunction with track footwear to sustain and direct the device's motion. These round steel components are purposefully positioned along the undercarriage frame and come in numerous types such as service provider rollers, track rollers, and idlers. Provider rollers aid in supporting the weight of the equipment, while track rollers help distribute the load and guarantee smooth track footwear expression (undercarriage parts). Idlers function as a tensioning mechanism for the track chain, keeping proper track stress for optimum performance.

To enhance durability and performance, rollers are typically created from high-grade materials like forged steel, supplying resistance to tear and put on under hefty loads and rough working conditions. Appropriate lubrication is vital to reduce friction in between the rollers and track footwear, expanding the lifespan of both parts. Normal inspection and upkeep of rollers are vital to avoid premature wear and prospective breakdowns, making certain the constant procedure of hefty equipment.

Idlers

Idlers play a critical duty in the undercarriage system of hefty machinery, acting as crucial components for maintaining appropriate track chain stress and making sure ideal machine performance. Idlers are accountable for leading the track chain and sustaining the weight of the tools. These cylindrical rollers are purposefully positioned along the track framework to distribute the maker's weight uniformly, minimize vibration, and improve stability during operation.

Effectively operating idlers aid protect against early wear on the track chain and various other undercarriage parts, inevitably extending the lifespan of the equipment. They additionally add to sustain effectiveness by reducing moving resistance and minimizing the power called for to move the equipment (undercarriage parts). Regular inspection and maintenance of useful content idlers are critical to discover any type of indications of wear, misalignment, or damage that could lead to efficiency concerns or downtime

Gears

Playing a crucial role in the undercarriage system of hefty equipment, gears are essential components liable for transferring power from the equipment to the track chain. Sprockets include toothed wheels or gears that mesh with the links of the track chain, making it possible for the equipment to propel ahead or backward. These parts are normally made from high-strength products like solidified steel to withstand the extreme stress and friction top article created during operation. Sprockets come in different sizes and tooth setups to match various device specs and applications. Correct upkeep and routine inspection of sprockets are vital to make certain optimum performance and expand their life-span. Issues such as worn-out teeth or misalignment can bring about lowered effectiveness and possible breakdowns. By understanding the importance of gears in the undercarriage system, drivers and upkeep workers can properly take care of these components to improve the total performance and integrity of hefty equipment.

Track Chains

An important part of the undercarriage system in hefty machinery, track chains play a crucial duty in directing the motion and sustaining of the tools. Track chains are durable steel chains that connect the drive sprocket to the wheels or tracks of the heavy equipment. These chains are created to sustain enormous tension, wear, and stress while making sure efficient and smooth procedure of the equipment.

Track chains are composed of specific links that are connected by pins and bushings. The layout of track chains is crucial as it directly affects the total performance and sturdiness of the hefty machinery. Appropriate upkeep of track chains is necessary to prevent premature wear, lower downtime, and expand the life-span of the tools.

Regular assessments, lubrication, and modifications are necessary to keep track chains in optimum condition. Failing to keep track chains can result in increased functional costs because of constant substitutes and repair why not look here services. Spending in top quality track chains and sticking to a rigorous maintenance schedule is crucial to taking full advantage of the efficiency and long life of heavy machinery.

Conclusion

To conclude, the crucial components for hefty equipment undercarriage components consist of track footwear, rollers, idlers, sprockets, and track chains. These components are important for the appropriate performance and procedure of heavy devices, providing security, grip, and support. It is vital for drivers and maintenance employees to regularly check and preserve these elements to ensure the security and efficiency of the machinery.

Key components such as track footwear, rollers, idlers, sprockets, and track chains play a pivotal function in the functionality and efficiency of these large makers (undercarriage parts). Provider rollers help in sustaining the weight of the tools, while track rollers assist disperse the tons and ensure smooth track shoe articulation. Idlers act as a tensioning system for the track chain, maintaining proper track stress for ideal efficiency

Track chains are durable metal chains that link the drive sprocket to the wheels or tracks of the heavy machinery.In final thought, the vital parts for hefty equipment undercarriage components include track footwear, rollers, idlers, gears, and track chains.

Report this page